Graphite Electrode Uses For Corundum Refining Electric Arc Fornace Small Diameter Fornax Electrodes

Technical Parameter

Chart I: Technical Parameter For Small Diameter Graphite Electrode

| Diameter | Pars | Resistentia | Flexurae Fortitudo | Iuvenis Modulus | Densitas | CTE | Cineres | |

| Inch | mm | μΩ·m | MPa | GPa | g/cm*3 | 10-6/ | % | |

| 3 | 75 | Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Papilla | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 4 | 100 | Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Papilla | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 6 | 150 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Papilla | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 8 | 200 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Papilla | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 9 | 225 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Papilla | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 10 | 250 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Papilla | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

Chart 2:Current Capacitas baiulans pro parva diametro Graphite Electrode

| Diameter | Current Load | Current Density | Diameter | Current Load | Current Density | ||

| Inch | mm | A | A/m2 | Inch | mm | A | A/m2 |

| 3 | 75 | 1000-1400 | 22-31 | 6 | 150 | 3000-4500 | 16-25 |

| 4 | 100 | 1500-2400 | 19-30 | 8 | 200 | 5000-6900 | 15-21 |

| 5 | 130 | 2200-3400 | 17-26 | 10 | 250 | 7000-1000 | 14-20 |

Chart 3: Graphite Electrode Size & Tolerance For Small Diameter Graphite Electrode

| Nominal Diameter | Actualis Diameter (mm) | Longitudo nominal | tolerantia | |||

| Inch | mm | Maximilianus. | Min. | mm | Inch | mm |

| 3 | 75 | 77 | 74 | 1000 | 40 | -75~+50 |

| 4 | 100 | 102 | 99 | 1200 | 48 | -75~+50 |

| 6 | 150 | 154 | 151 | 1600 | 60 | ±100 |

| 8 | 200 | 204 | 201 | 1600 | 60 | ±100 |

| 9 | 225 | 230 | 226 | 1600/180 | 60/72 | ±100 |

| 10 | 250 | 256 | 252 | 1600/180 | 60/72 | ±100 |

Pelagus Application

- Calcium carbide excoquunt

- Carborundum productione

- Corundum conflans

- Rara metalla excoquunt

- Ferosilicon plantae refractarium

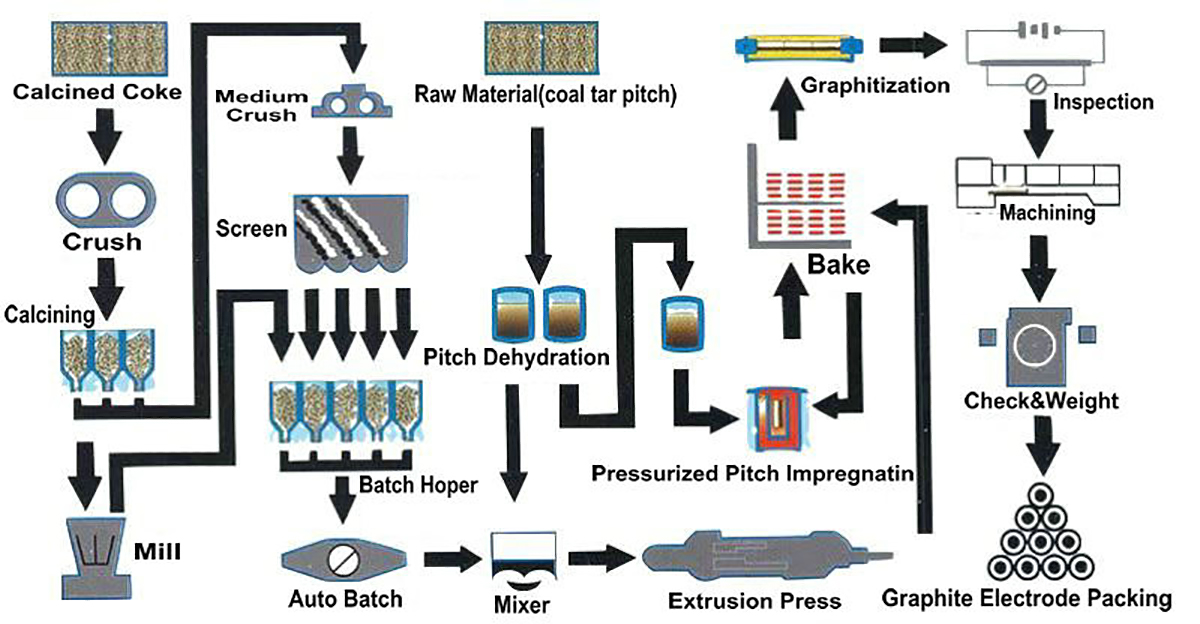

RP Graphite Electrode Production Process

Gufan Commoda

1. Ex materia graphite alta qualitas, nostri parvae diametri graphite electrodes aedificantur ad extremas temperaturas sustinendas et optimam electricam conductivity praebent. Hoc efficit ut processus stabilis et efficiens excoquunt, unde fit in superiori qualitate producti ac deminuto energiae consummationis.

2. Minima harum electrodes magnitudo permittit subtilius imperium in processu excoquunt, eosque perficit ad applicationes quae altam accurationem et lepidissimam eventum requirunt. Sive mixturas sive conflatorias metalla produces, electrodes nostri te adiuvabunt ut optatum exitum singulari praecisione consequaris.

3. Electrodes nostri parvae diametri graphitei aptae sunt amplis industriis, incluso ferro fabricandi, processui chemico, et metallico mittentes. Nulla materia magnitudinem operationis tuae, nativus electrodes nostri potest occurrere certis postulationibus tuis.

4. In ferro fabricando, electrodes nostri parvae diametri graphite adhibentur in fornacibus electricis, ubi munus cruciale exercent in ferro GENERALI producendo. Minoris amplitudo permittit ut certa potestas super processum liquefactum, ut constantes eventus et extenuando vastitatem capiat.

5. In processu chemico, nostri electrodes essentiales sunt ad calcii carbidam producendam et ad carborundum elegantiam. Hi processus accuratam temperaturam continent, quam nostri electrodes diligentissime liberant.

6. Ad metallum fusurae, nostri diametri graphitei parvae electrodes in metallis rarioribus et ferrosilicon plantarum excoquunt. Superior conductivity graphite permittit efficiens metallis liquefactionem, unde fit in velocioribus cyclis productionis et altiore altiore productivo.