HP24 Graphite Carbon Electrodes Dia 600mm Electrical Arc Furnace

Technical Parameter

| Parameter | Pars | Unitas | HP 600mm(24") Data |

| Nominal Diameter | Electrode | mm (inch) | 600 |

| Max Diameter | mm | 613 | |

| Min Diameter | mm | 607 | |

| Longitudo nominal | mm | 2200/2700 | |

| Max Longitudo | mm | 2300/2800 | |

| Min Longitudo | mm | 2100/2600 | |

| Current Density | KA/cm2 | 13-21 | |

| Current Capacitas baiulans | A | 38000-58000 | |

| Imprimis resistentia | Electrode | μΩm | 5.2-6.5 |

| Papilla | 3.2-4.3 | ||

| Flexurae Fortitudo | Electrode | Mpa | ≥10.0 |

| Papilla | ≥22.0 | ||

| Modulus | Electrode | Gpa | ≤12.0 |

| Papilla | ≤15.0 | ||

| mole Density | Electrode | g/cm*3 | 1.68-1.72 |

| Papilla | 1.78-1.84 | ||

| CTE | Electrode | 10-6/ | ≤2.0 |

| Papilla | ≤1.8 | ||

| Cinis Content | Electrode | % | ≤0.2 |

| Papilla | ≤0.2 |

NOTE: Quaelibet specifica exigentia in dimensione offerri potest.

Graphite Electrode cum Electric Arc fornace

Electrodes graphitae cruciales sunt componentes in fornace electrica arcus (EAF) processu ferrario facto. Nihilominus, sumptus de chalybe processu oxidationis electrode, sublimationis, dissolutionis, comminutionis, et fractionis afficitur. Bonum nuntium est graphite electrode delectu, usu, sustentatione, electrode consumptionem efficaciter reducere posse. In hoc articulo, disseremus quomodo eligat electrodam graphite ius et quam proprie teneas, ut plus ex tua collocatione capias.

Specifications

Compositus inter capacitatem fornacem electricam, transformator oneris potentiae et magnitudinis electrode.

| Capacitas fornacis | Diameter interior (m) | Transformer Capacitas (MVA) | Graphite Electrode Diameter (mm) | ||

| UHP | HP | RP | |||

| 10 | 3.35 | 10 | 7.5 | 5 | 300/350 |

| 15 | 3.65 | 12 | 10 | 6 | 350 |

| 20 | 3.95 | 15 | 12 | 7.5 | 350/400 |

| 25 | 4.3 | 18 | 15 | 10 | 400 |

| 30 | 4.6 | 22 | 18 | 12 | 400/450 |

| 40 | 4.9 | 27 | 22 | 15 | 450 |

| 50 | 5.2 | 30 | 25 | 18 | 450 |

| 60 | 5.5 | 35 | 27 | 20 | 500 |

| 70 | 6.8 | 40 | 30 | 22 | 500 |

| 80 | 6.1 | 45 | 35 | 25 | 500 |

| 100 | 6.4 | 50 | 40 | 27 | 500 |

| 120 | 6.7 | 60 | 45 | 30 | 600 |

| 150 | 7 | 70 | 50 | 35 | 600 |

| 170 | 7.3 | 80 | 60 | --- | 600/700 |

| 200 | 7.6 | 100 | 70 | --- | 700 |

| 250 | 8.2 | 120 | --- | --- | 700 |

| 300 | 8.8 | 150 | --- | --- | |

Instructionem pro tradendo et utendo

- 1. Remove tegumento tutelae novae foraminis electrodis, vide num stamina in perforato electrode perfecta sit et stamina incompleta, contactus fabrum professionalium ad dijudicandum an electrode adhiberi possit;

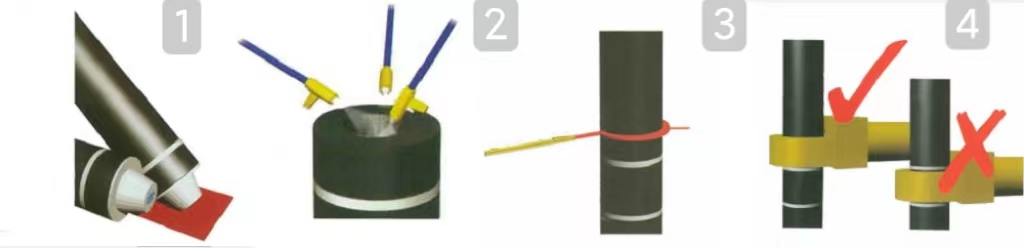

- 2. Screw electrode assecula in uno fine foraminis electronici, et pulvinum molle sub altero fine electronico pone, ad vitandum iuncturam electronicodam damno; (vide pic1)

- 3. Utere aere compresso, ut pulverem et varias in superficie et foramine electrode connectentis sufflaas, et deinde superficiem et connexum novae electrode purgabis, eam penicillo purga; (see pic2)

- 4

- 5. Aureus proprio valore uti ad electrodem proprie claudendi; (see pic3)

- 6.Clamp possessor extra terrorem acies collocari debet. (see pic4)

- 7. In periodo expolitione facile est electrodam tenuem facere et fractionem facere, iuncturam excidere, consumptionem electrodis augere, electrodes non placet ut carbo contentum moveat.

- 8. Ob varias materias rudis ab unoquoque fabricando et processu fabricando adhibitas, proprietates physicas et chemicas electrodum et artuum singulorum opificum. Ita in usu, in communibus adiunctis, Quaeso ne mixta electrodes et iuncturas a diversis artifices productas adhibeas.