UHP 500mm Dia 20 Inch Fornax Graphite Electrode Cum Papillis

Technical Parameter

Physica & Chemical Properties For D500mm(20") Electrode & Nipple

| Parameter | Pars | Unitas | UHP 500mm(20") Data |

| Nominal Diameter | Electrode | mm (inch) | 500 |

| Max Diameter | mm | 511 | |

| Min Diameter | mm | 505 | |

| Longitudo nominal | mm | 1800/2400 | |

| Max Longitudo | mm | 1900/2500 | |

| Min Longitudo | mm | 1700/2300 | |

| Max Current Densitas | KA/cm2 | 18-27 | |

| Current Capacitas baiulans | A | 38000-55000 | |

| Imprimis resistentia | Electrode | μΩm | 4.5-5.6 |

| Papilla | 3.4-3.8 | ||

| Flexurae Fortitudo | Electrode | Mpa | ≥12.0 |

| Papilla | ≥22.0 | ||

| Modulus | Electrode | Gpa | ≤13.0 |

| Papilla | ≤18.0 | ||

| mole Density | Electrode | g/cm*3 | 1.68-1.72 |

| Papilla | 1.78-1.84 | ||

| CTE | Electrode | 10-6/ | ≤1.2 |

| Papilla | ≤1.0 | ||

| Cinis Content | Electrode | % | ≤0.2 |

| Papilla | ≤0.2 |

NOTE: Quaelibet specifica exigentia in dimensione offerri potest.

Applications

- Arcus Electric Fornace

Electrode graphite principaliter adhibita sunt in processu ferrario moderno, Fornax Electric Arcus inter efficacissima et certa instrumenta divulgata est. Fornax electrica arcus graphite electrodes utitur ad altas temperaturas et ad venam generandam creandam, quae tunc exiguo ferro REDIVIVUS liquescere solebat. Sicut diameter electrodis graphite agit vitale munus in creando gradu necessario caloris et ad finem producti summus qualitas, usus ius electrode pendet ad optimos eventus assequendos. Secundum capacitatem fornacis electrici, diversae diametri graphite electrodes instructae sunt ut electrodes graphitae utantur, electrode graphitae a papillis connexae sunt. - Submersa Electric Fornax

Fornax electrica submersa est productum revolutionarium quod ad necessitates hodiernae industriae destinatur. Hic status fornax-of-artis notat electrode graphite UHP qui specialiter fabricatus est ad efficientiam processus liquefactionis emendandam. Electrode graphita in fornace Electric submersa maxime adhibita est ad producendum ferroalloys, purum silicon, phosphorus luteum, matte et calcium carbide. Unicum consilium huius fornacis electrici seorsum a fornacibus traditis eam ponit, cum partem electrode conductivi in materiarum incurrens sepeliri sinit. - Resistentia fornacis

Resistentia fornacibus adhibita sunt ad producendos productos graphites summus qualitas ut electrodes graphitici UHP. Hae electrodes late utuntur in fornace electrica chalybem processum ad efficiendum ferrum summus. Electrode graphite UHP notum est propter altam conductivity scelerisque, resistentiam electricam, et resistentiam ad concussionem thermarum. Hae proprietates specimen electionis faciunt ad processum chalybem. UHP electrodes graphite producuntur per processum graphitizationem temperatum intra fornacem resistentem.

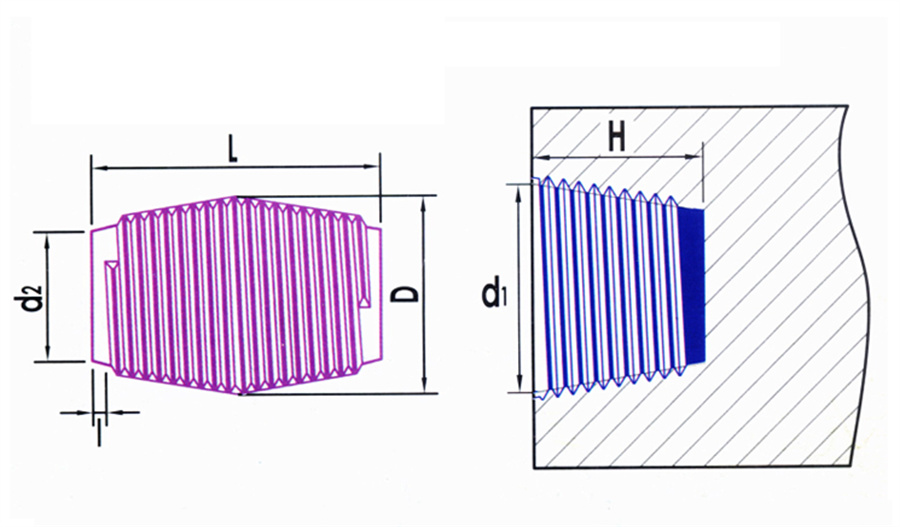

Gufan Cabon Conical Papilla et Socket Drawing

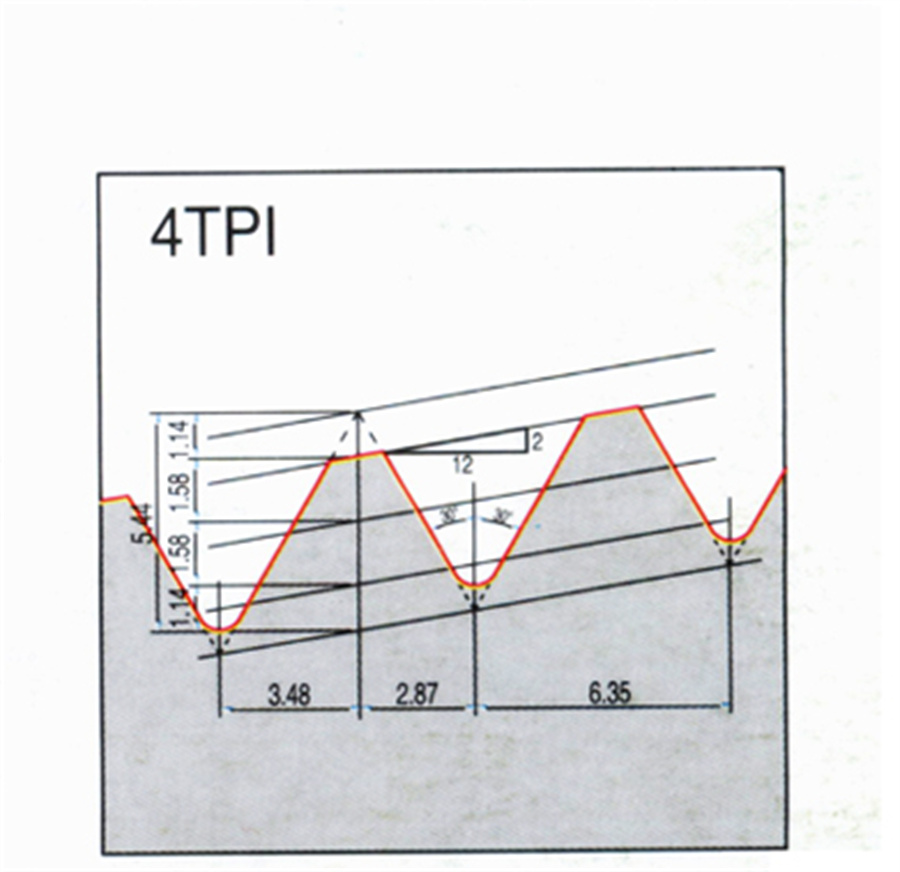

Gufan Carbon Conical Papilla et Socket Dimensiones (4TPI)

| Gufan Carbon Conical Papilla et Socket Dimensiones (4TPI) | |||||||||

| Nominal Diameter | IEC Code | Magnitudines Papillae (mm) | Moles Pentium (mm) | Thread | |||||

| mm | inch * | D | L | d2 | I | d1 | H | mm | |

| tolerantia (-0.5~0) | Tolerantia (1~0) | Tolerantia (-5~0) | Tolerantia (0~0.5) | Tolerantia (0-7) | |||||

| 200 | 8 | 122T4N | 122.24 | 177.80 | 80.00 | <7 | 115.92 | 94.90 | 6.35 |

| 250 | 10 | 152T4N | 152.40 | 190.50 | 108.00 | 146.08 | 101.30 | ||

| 300 | 12 | 177T4N | 177.80 | 215.90 | 129.20 | 171.48 | 114.00 | ||

| 350 | 14 | 203T4N | 203.20 | 254.00 | 148.20 | 196.88 | 133.00 | ||

| 400 | 16 | 222T4N | 222.25 | 304.80 | 158.80 | 215.93 | 158.40 | ||

| 400 | 16 | 222T4L | 222.25 | 355.60 | 150.00 | 215.93 | 183.80 | ||

| 450 | 18 | 241T4N | 241.30 | 304.80 | 177.90 | 234.98 | 158.40 | ||

| 450 | 18 | 241T4L | 241.30 | 355.60 | 169.42 | 234.98 | 183.80 | ||

| 500 | 20 | 269T4N | 269.88 | 355.60 | 198.00 | 263.56 | 183.80 | ||

| 500 | 20 | 269T4L | 269.88 | 457.20 | 181.08 | 263.56 | 234.60 | ||

| 550 | 22 | 298T4N | 298.45 | 355.60 | 226.58 | 292.13 | 183.80 | ||

| 550 | 22 | 298T4L | 298.45 | 457.20 | 209.65 | 292.13 | 234.60 | ||

| 600 | 24 | 317T4N | 317.50 | 355.60 | 245.63 | 311.18 | 183.80 | ||

| 600 | 24 | 317T4L | 317.50 | 457.20 | 228.70 | 311.18 | 234.60 | ||