Fornax in Ferro Smelting.

Technical Parameter

Chart I: Technical Parameter For Small Diameter Graphite Electrode

| Diameter | Pars | Resistentia | Flexurae Fortitudo | Iuvenis Modulus | Density | CTE | Cineres | |

| Inch | mm | μΩ·m | MPa | GPa | g/cm*3 | 10-6/ | % | |

| 3 | 75 | Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Papilla | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 4 | 100 | Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Papilla | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 6 | 150 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Papilla | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 8 | 200 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Papilla | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 9 | 225 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Papilla | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 10 | 250 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Papilla | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

Chart 2:Current Capacitas baiulans pro parva diametro Graphite Electrode

| Diameter | Current Load | Current Density | Diameter | Current Load | Current Density | ||

| Inch | mm | A | A/m2 | Inch | mm | A | A/m2 |

| 3 | 75 | 1000-1400 | 22-31 | 6 | 150 | 3000-4500 | 16-25 |

| 4 | 100 | 1500-2400 | 19-30 | 8 | 200 | 5000-6900 | 15-21 |

| 5 | 130 | 2200-3400 | 17-26 | 10 | 250 | 7000-1000 | 14-20 |

Chart 3: Graphite Electrode Size & Tolerance For Small Diameter Graphite Electrode

| Nominal Diameter | Actualis Diameter (mm) | Longitudo nominal | tolerantia | |||

| Inch | mm | Maximilianus. | Min. | mm | Inch | mm |

| 3 | 75 | 77 | 74 | 1000 | 40 | -75~+50 |

| 4 | 100 | 102 | 99 | 1200 | 48 | -75~+50 |

| 6 | 150 | 154 | 151 | 1600 | 60 | ±100 |

| 8 | 200 | 204 | 201 | 1600 | 60 | ±100 |

| 9 | 225 | 230 | 226 | 1600/180 | 60/72 | ±100 |

| 10 | 250 | 256 | 252 | 1600/180 | 60/72 | ±100 |

Pelagus Application

- Calcium carbide excoquunt

- Carborundum productione

- Corundum conflans

- Rara metalla excoquunt

- Ferosilicon plantae refractarium

Instructionem tradere et usus Graphite Electrodes

1.Use speciales instrumenta elevatio ad vitam graphite electrode ne laedatur per translationem. (vide pic1)

2.Graphite electrode arcendus est, ne madefactis vel umidis pluviis, nix, siccescat. (vide pic2).

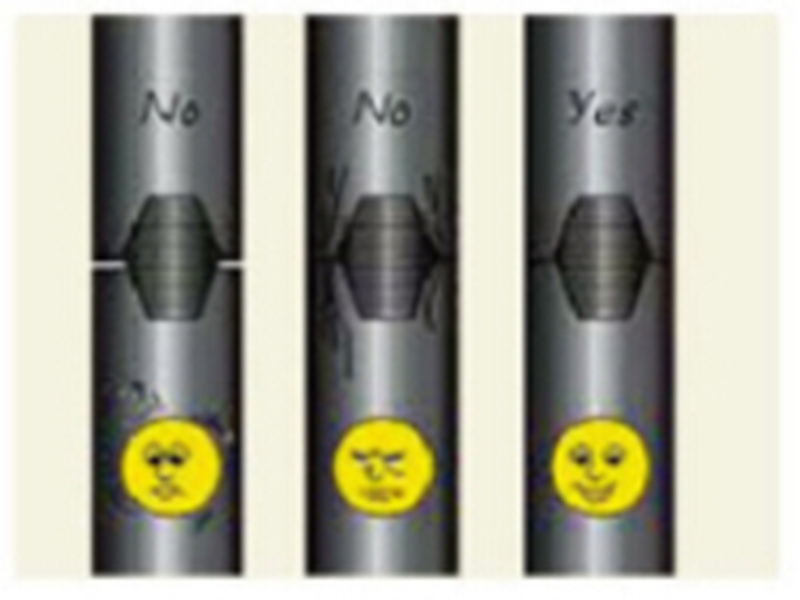

3.Care inprimendo ante usum nervum et umbilicum, apta ad usum, inspectionem pro pice, obturaculum (vide pic3).

4.Clean papilla et acetabula stamina a compresso aere. (vide pic4)

5. Ante usum, electrode graphite in fornace desiccari debet, siccus siccus minus quam 150℃ debet, tempus aridi plus quam XXX horarum esse debet.

6.Graphite electrode coniungi debet arcte et recta congruis tensis torque.

7. Ad fracturam electrodis graphite evitandam, magnam partem in inferiori loco et parvam partem in superiori loco pone.