Fornax electrici fornax arcus electrici pro ferro et industria liquatur

Technical Parameter

Chart I: Technical Parameter For Small Diameter Graphite Electrode

| Diameter | Pars | Resistentia | Flexurae Fortitudo | Iuvenis Modulus | Densitas | CTE | Cineres | |

| Inch | mm | μΩ·m | MPa | GPa | g/cm*3 | 10-6/ | % | |

| 3 | 75 | Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Papilla | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 4 | 100 | Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Papilla | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 6 | 150 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Papilla | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 8 | 200 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Papilla | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 9 | 225 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Papilla | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 10 | 250 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Papilla | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

Chart 2:Current Capacitas baiulans pro parva diametro Graphite Electrode

| Diameter | Current Load | Current Density | Diameter | Current Load | Current Density | ||

| Inch | mm | A | A/m2 | Inch | mm | A | A/m2 |

| 3 | 75 | 1000-1400 | 22-31 | 6 | 150 | 3000-4500 | 16-25 |

| 4 | 100 | 1500-2400 | 19-30 | 8 | 200 | 5000-6900 | 15-21 |

| 5 | 130 | 2200-3400 | 17-26 | 10 | 250 | 7000-1000 | 14-20 |

Chart 3: Graphite Electrode Size & Tolerance For Small Diameter Graphite Electrode

| Nominal Diameter | Actualis Diameter (mm) | Longitudo nominal | tolerantia | |||

| Inch | mm | Maximilianus. | Min. | mm | Inch | mm |

| 3 | 75 | 77 | 74 | 1000 | 40 | -75~+50 |

| 4 | 100 | 102 | 99 | 1200 | 48 | -75~+50 |

| 6 | 150 | 154 | 151 | 1600 | 60 | ±100 |

| 8 | 200 | 204 | 201 | 1600 | 60 | ±100 |

| 9 | 225 | 230 | 226 | 1600/180 | 60/72 | ±100 |

| 10 | 250 | 256 | 252 | 1600/180 | 60/72 | ±100 |

Pelagus Application

- Calcium carbide excoquunt

- Carborundum productione

- Corundum conflans

- Rara metalla excoquunt

- Ferosilicon plantae refractarium

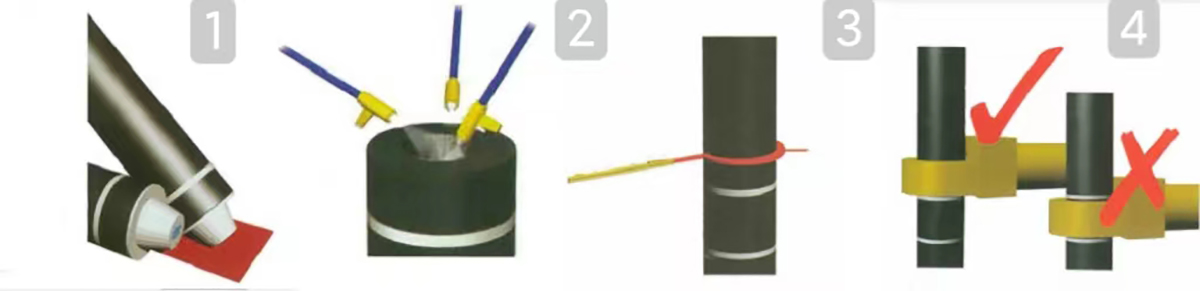

Instructionem tradere et usus Graphite Electrodes

1. Remove tegumento tutelae novae foraminis electrodis, vide num stamina in perforato electrode perfecta sit et stamina incompleta, contactus fabrum professionalium ad dijudicandum an electrode adhiberi possit;

2.Screw assecula electrode in uno fine foraminis electronici, et pulvinum mollem pone sub altero fine electronici ad vitandum electronico articulum laedendum;

3. Utere aere compresso, ut pulverem et varias in superficie et foramine electrode connectentis sufflaas, et deinde superficiem et connexum novi electrodis purgabis, eam penicillo purgabis;

4

5.Use Aureus propriis valorem ad recte claudunt electrode (videatur pic3)

6.Clamp possessor poni extra terrorem agmen.

7. In periodo expolitione facile est electrodam tenuem facere et fractionem facere, iuncturam excidere, consumptionem electrodis augere, electrodes non placet ut carbo contentum moveat.

8. Ob varias materias rudis ab unoquoque fabricando et processu fabricando adhibitas, proprietates physicas et chemicas electrodum et artuum singulorum opificum. Ita in usu, in communibus adiunctis, Quaeso ne mixta electrodes et iuncturas a diversis artifices productas adhibeas.